Medical Facilities

Building size: 23,385 Square feet

Architectural:

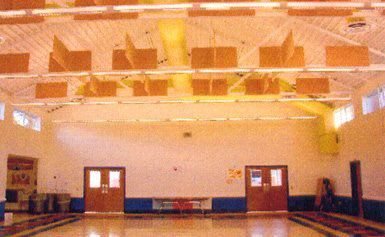

This 56-unit school building utilized panelized, component and modular constructions and included a 14- foot clearstory multipurpose room as the core area surrounded by office and classrooms, color accented walls accented tiled floors, storage cabinet, counters and shelving. The exterior stucco wall covering featured a horizontal visual

Accent and painted corrugated steels panels above with split face book foundation. The roof parapet was accented with peaked roofs and barrels vault canopies

Technical Innovation:

The 2.700 square foot multi-purpose room required site erection of five factory built floor section and several peaked steel roof trusses that spanned 42 feet, creating a 14-foot high clerestory structure. The lobby area featured large glass window panels and storefront doors coupled with built-in benches topped with corian®. Floors in the multipurpose room were pre-fabricated at the factory, shipped and filled concrete on site.

Building size: (3) School Addition-

Totaling 15,346 Sq Ft

Architectural:

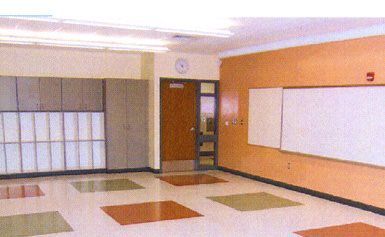

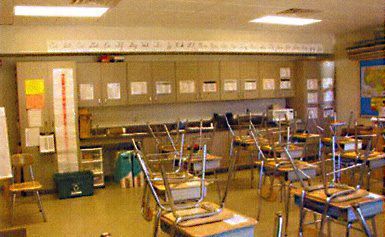

This project involved three different school additions with in the school district and ranged in size form 3696 to 5918 square feet. Each modular building addition was attached directly to the existing school. All Buildings featured connecting corridors and Classrooms with painted gypsum walls, tiled floor and acoustical ceiling. All exteriors were bricked on site to match the existing school.

Technical Innovation:

Time was of the essence for this school district due to the increased enrollment. All additions were built simultaneously at the factory to facilitate timely shipment and delivery. Once delivered to the sites, construction crews were able to work at all three sites at the same time, completing the project just in time for the opening of school in September.

Building size: 25,000

Architectural:

This school addition is a three-story facility with 5 classrooms per floor, plus boys and girls bathrooms and storage rooms, and includes a fourth story equipment penthouse also

Built at the factory. The exterior is full face brick to match the existing school, while the interior is finished with painted drywall ceramic walls in the corridors and bathrooms and ceramic floors in the bathrooms with colorful vinyl tile at the remaining floor areas. The building is comprised of 48 modules of varying sizes, put together side by side and end to end to precisely fit the school existing profile. Pre poured concrete floors and stairs completed at the plant replace the traditional slab on grade, providing the permanence and performance of conventional construction. Spray fireproofing was also completed at the paint between floors.

Technical Innovation:

The building is non-combustible structural steel post and beam construction for optimal flexibility for any future renovations, all but the exterior finishes were completed at the factory, including millwork, tack and marker boards, keeping the on-site time down to minimum. The modular addition had to meet the existing school at three different elevations, presenting challenges because the varying levels in the existing building on their three floors had a 6” slop from one to the other. This required an innovated solution-the factory had to create a concrete ramp within the modular building so that the opening and floors levels between the two structures on all three levels were perfectly aligned. Large HVAC units were factory installed in the prefabricated penthouse, complete with all insulated piping-ready for hook up at the site. This prevented the local contractors from leaving to site install an enormous amount of HVAC equipment.